XPS CARBON ECO

XPS CARBON ECO is the ideal solution for insulating a cottage from the foundation to the roof. High strength and low thermal conductivity have made this material popular among professional builders. XPS does not absorb water, does not swell or shrink, is chemical resistant and does not rot. The service life of the material is at least 50 years. XPS TECHNONICOL CARBON ECO has a voluntary certification “Leaf of Life”, which confirms the safety of use in housing construction. This is an excellent thermal insulation material for those looking for high-quality thermal insulation with high performance.

XPS TECHNONICOL CARBON ECO are universal slabs made of extruded polystyrene foam, which can be used to insulate a cottage from the foundation to the roof. XPS is environmentally friendly, which is confirmed by the “Leaf of Life” eco-label – the only certification in Russia accepted by the international expert community. The insulation has a closed-porous and homogeneous structure with a small cell size, which provides the material with strength, low thermal conductivity and water absorption. Extruded polystyrene foam is not afraid of rodents, it does not rot, and is resistant to chemical influences and aggressive environmental conditions. The material makes it possible to achieve effective insulation and is optimally suited for thermal insulation of external structures in low-rise and cottage construction.

LOW THERMAL CONDUCTIVITY

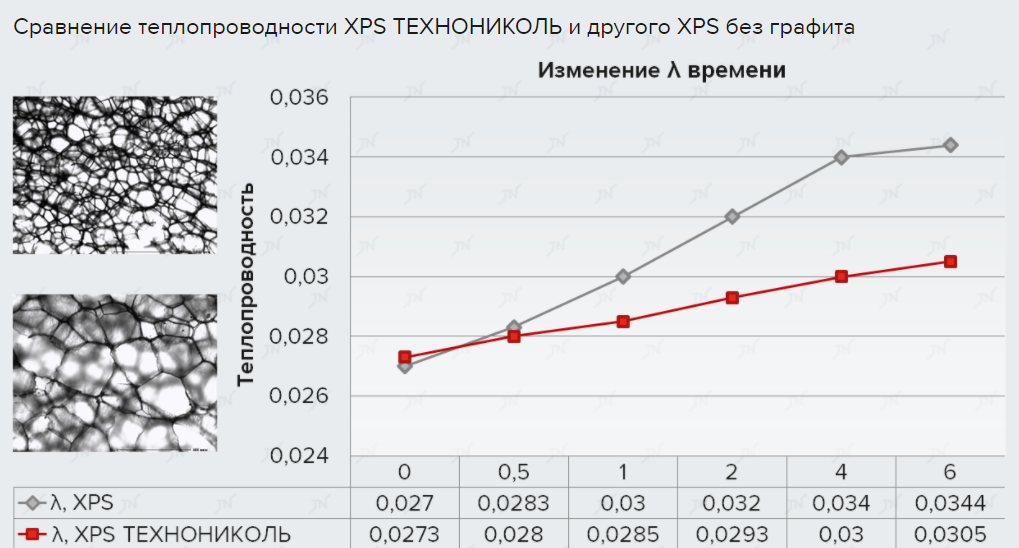

TECHNONICOL CARBON ECO extruded polystyrene foam consists of many small closed cells with a diameter of 0.1–0.2 mm, which provide low thermal conductivity of the material in the range of 0.030–0.033 W/m*K at (25±5) ºC.

The graph shows that thanks to nongraphite, the thermal conductivity of the material is stable throughout its entire service life.

Thermal insulation thickness calculator

HIGH STRENGTH

Extruded polystyrene foam CARBON ECO has high compressive strength, which at 10% linear deformation is at least 150 kPa for slabs up to 40 mm and at least 200 kPa for greater thickness.

LOW WATER ABSORPTION

TECHNONICOL XPS boards have low water absorption, which means the material is resistant to moisture. The fine-cell structure of the material ensures an almost zero coefficient of water absorption. Therefore, extruded polystyrene foam CARBON ECO does not accumulate moisture, does not deform due to temperature changes, does not change its volume and does not change geometry throughout its service life, and is also resistant to the formation of mold and mildew. But the main thing is that the material does not lose its heat-insulating properties in a humid environment.

EASY INSTALLATION

Extruded polystyrene foam is a lightweight yet durable material. Therefore, TECHNONICOL XPS slabs are easy to transport and store, and can even be installed alone. The use of an L-edge simplifies installation and solves the problem of cold bridges.

ENVIRONMENTAL AND SAFETY

Extruded polystyrene foam CARBON ECO is an environmentally friendly and safe material. According to research by the Federal State Budgetary Institution Research Institute of Rospotrebnadzor, it does not emit harmful substances. XPS is highly bioresistant, according to the Biostability Research Center of the Moscow State University Ecocenter, and research from the Institute of Disinfectology has confirmed that the material is not a breeding ground for rodents. CARBON ECO boards carry the “Leaf of Life” label, recognized internationally by the World Eco-Labelling Association, and also meet LEED green building standards.

Expert assessment of the applicability of TECHNONICOL XPS materials certified according to LEED

DURABILITY

Extruded polystyrene foam boards can last at least 50 years. The durability of the material is confirmed by research by the Research Institute of Physics of the Russian Academy of Agricultural Sciences. The homogeneity of the structure and the addition of graphite nanoparticles to the XPS material allow TECHNONICOL CARBON ECO boards to maintain stable characteristics throughout their entire service life.

PLATE OPTIONS

CARBON ECO slabs are produced with an L-edge on all four sides (it allows the slabs to be laid without through seams and reduces heat loss at the joints).

Smooth edge slab L-edge slab

Slabs with an L-edge, unlike slabs with a smooth edge,

do not have cold bridges at the joints through which heat escapes.

In addition, the L-edge (also called the L-edge) is easier to install.

TECHNONICOL CARBON ECO XPS slabs with L-edge are available in sizes 1180 x 580 mm, starting from a thickness of 30 mm. The 20 mm thick slabs have a smooth edge and dimensions 1200 x 600 mm. Slabs of other sizes can be produced upon request.

ThermoBonding technology is used to produce slabs with a thickness of 80 mm or more. It is possible to form blocks up to 400 mm thick by sequentially gluing slabs of standard thickness by heating the upper layers of the material. The adhesion of individual plates occurs at the macromolecular level, so they have high tensile strength characteristics of the layers.

Table of all options:

| Thickness, mm | 20 | thirty | 40 | 50 | 100 |

| Length, mm | 1200 | 1180 | 1180 | 1180 | 1180 |

| Width, mm | 600 | 580 | 580 | 580 | 580 |

| Number of slabs in a pack, pcs. | 20 | 13 | 10 | 8 | 4 |

| Product area in a pack, m2 | 14.4 | 8.9 | 6.8 | 5.5 | 2.7 |

| Product volume in one pack, m 3 | 0.29 | 0.27 | 0.27 | 0.27 | 0.27 |

MAIN ADVANTAGES OF TECHNONICOL CARBON ECO PLATES

- Easy and convenient installation.

- High strength indicators.

- Low water absorption, resistant to mold and mildew.

- Safe for humans and the environment, do not emit harmful substances.

- Service life of at least 50 years without loss of properties.

Reviews

There are no reviews yet.